Aniai · 2024-2025

Building the Tools Behind Smarter Robots

As a founding product designer at a robotics startup, I played a key role in both design and product strategy, working closely with cross-functional teams to define how robots are built, tested, and managed.

Designing speed for robot development (2024-2025)

Robots handle a delicate job — even a few millimeters of deviation can make the difference between success and failure. To ensure reliability, robots must be tested under extreme conditions.

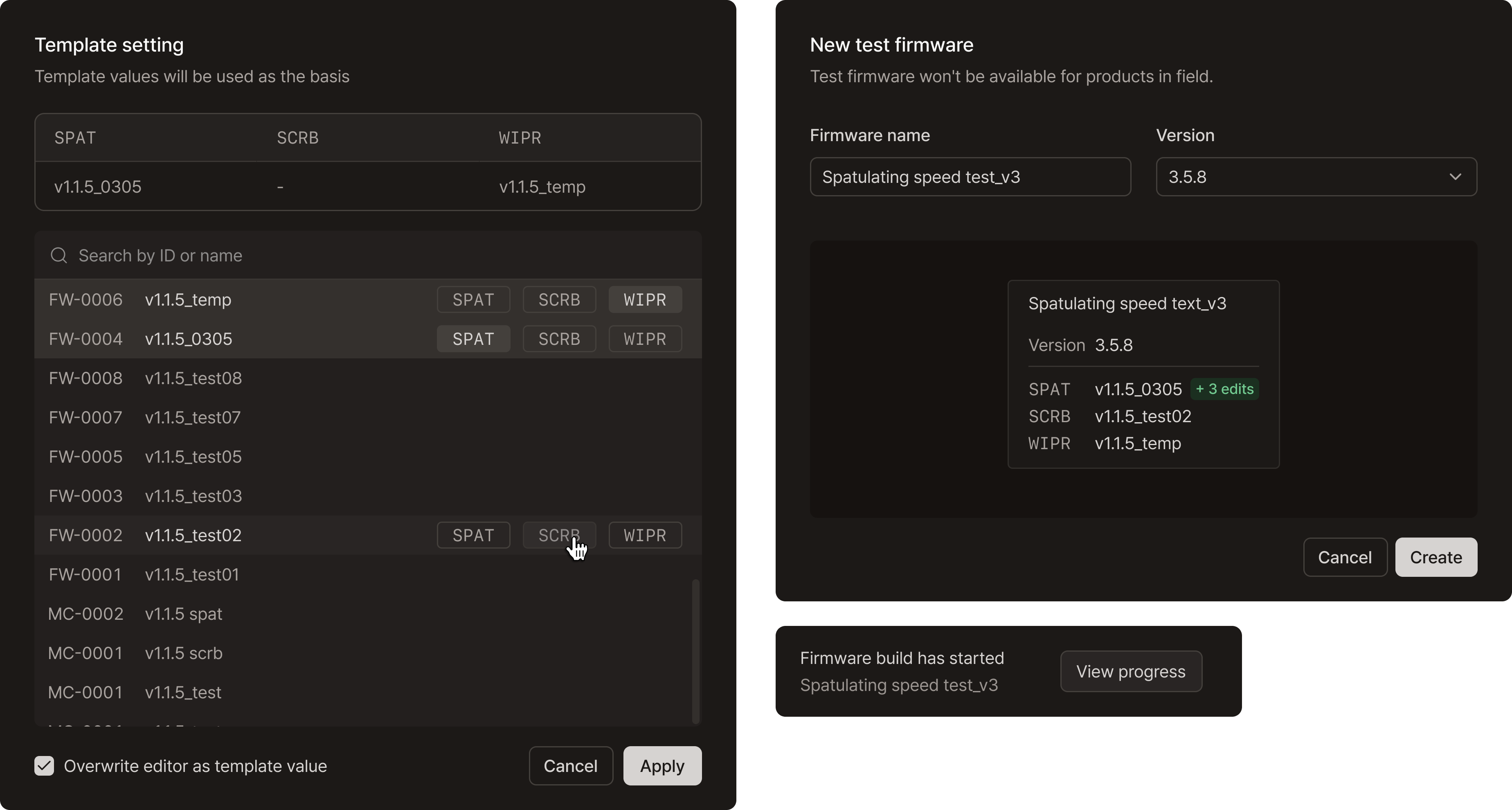

Our team needed a platform for engineers with little programming experience to adjust minor robot actions (e.g., the number of repetitions) for testing.

With the renewal of our internal platform, I reimagined this workflow: from request–response to direct control. Instead of a back-and-forth pipeline, I wanted robot and QA engineers to directly control robot actions themselves with key parameters1 — quickly, confidently, and safely.

Because every edit has real impact, I designed the parametric firmware generator around guidance, clarity, and control. The layout was designed for quick scanning and info panel provides guidance on parameters so that users can adjust without guesswork.

The test firmware generator accelerated development process tremendously. The average time to create test firmware reduced from 2-3 business days to 5 minutes, and the number of tests conducted during the same time span has increased by 3x.

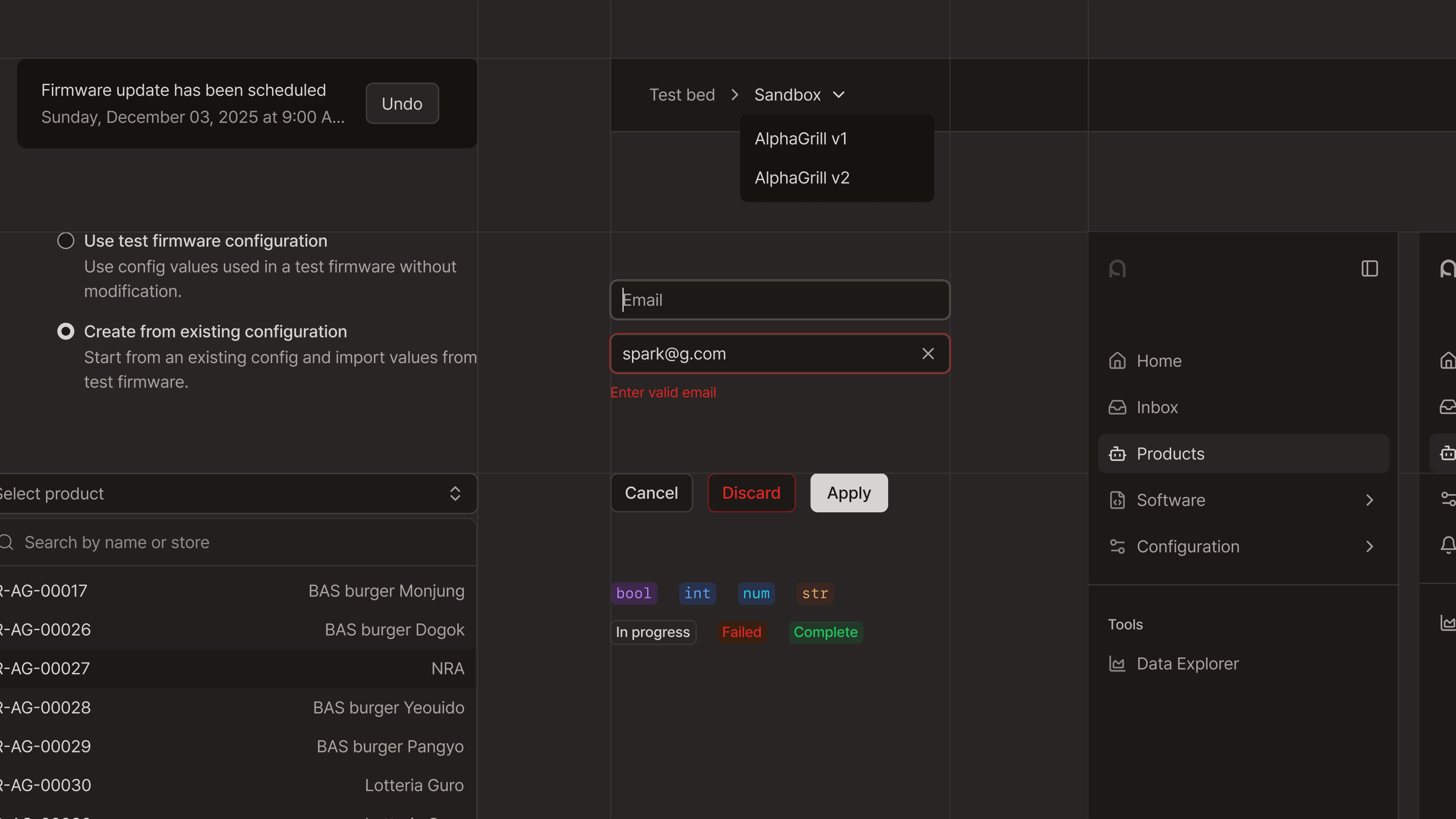

Scaling robot updates with confidence (2025)

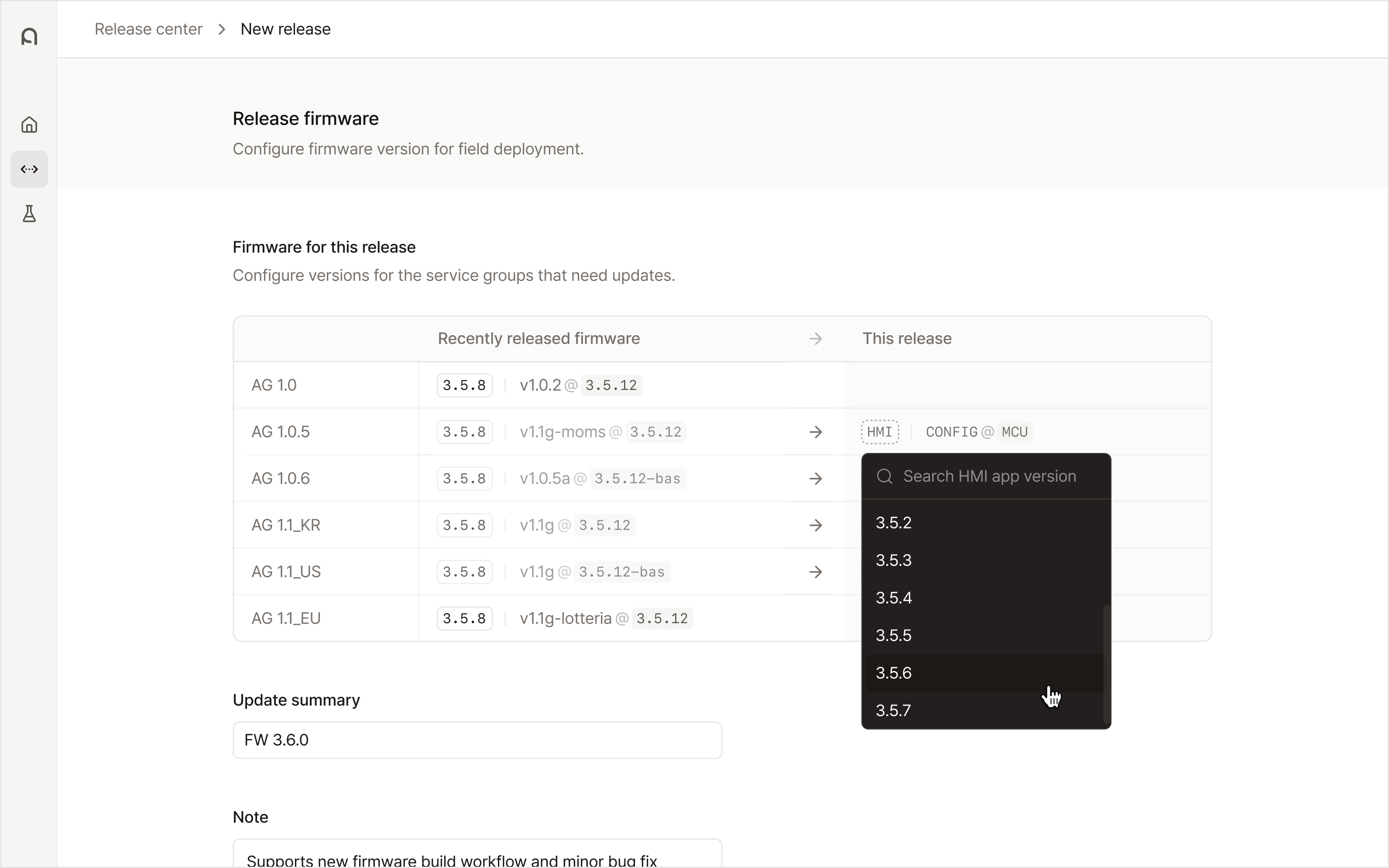

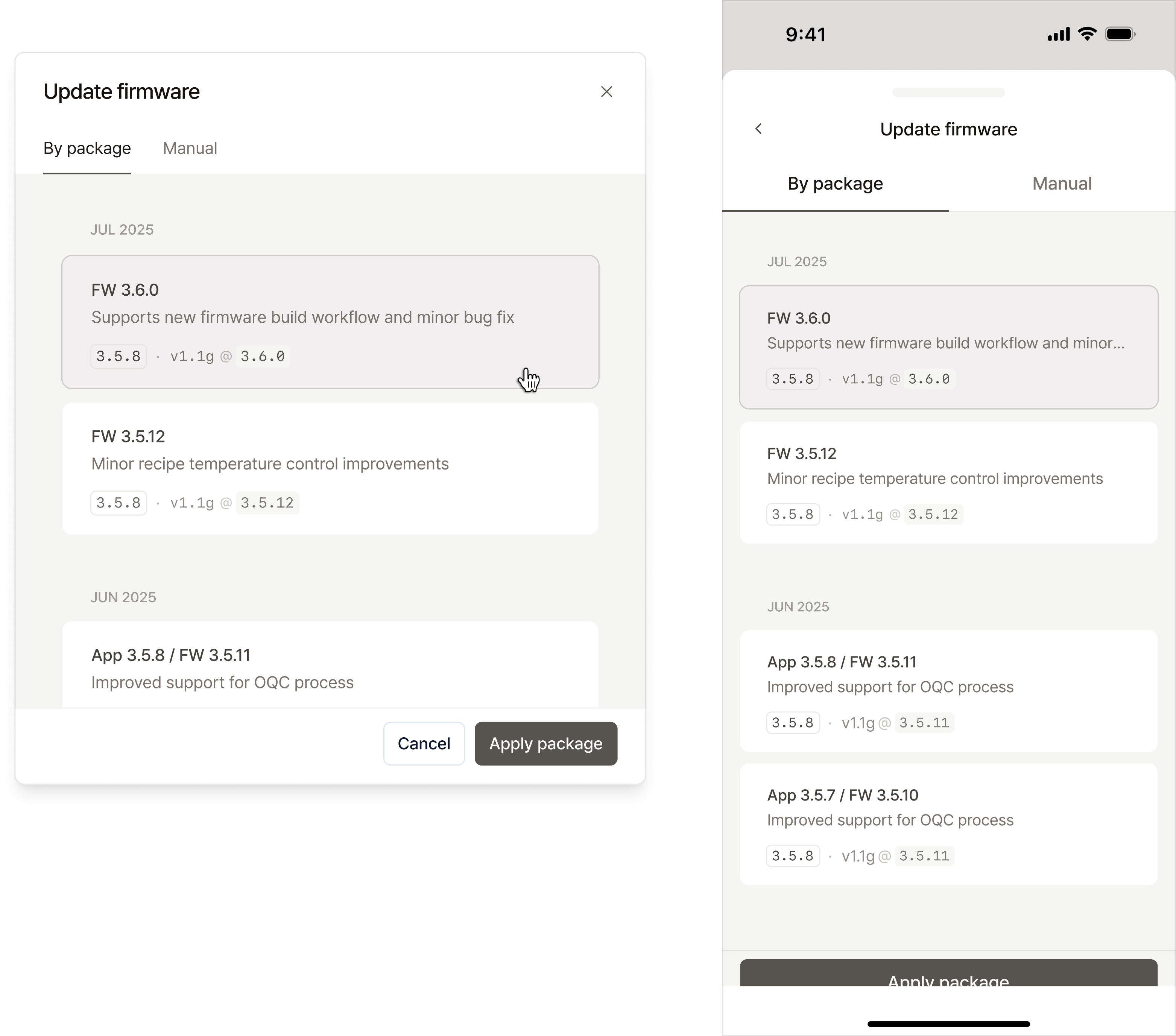

Timely robot upgrades are critical — customers expect smooth updates without downtime. But as we scaled to mass production and began supporting multiple robot versions, the effort to coordinate updates grew rapidly.

We needed an update management system that everyone — from robot engineers and product managers to manufacturing and field service — could rely on to coordinate updates.

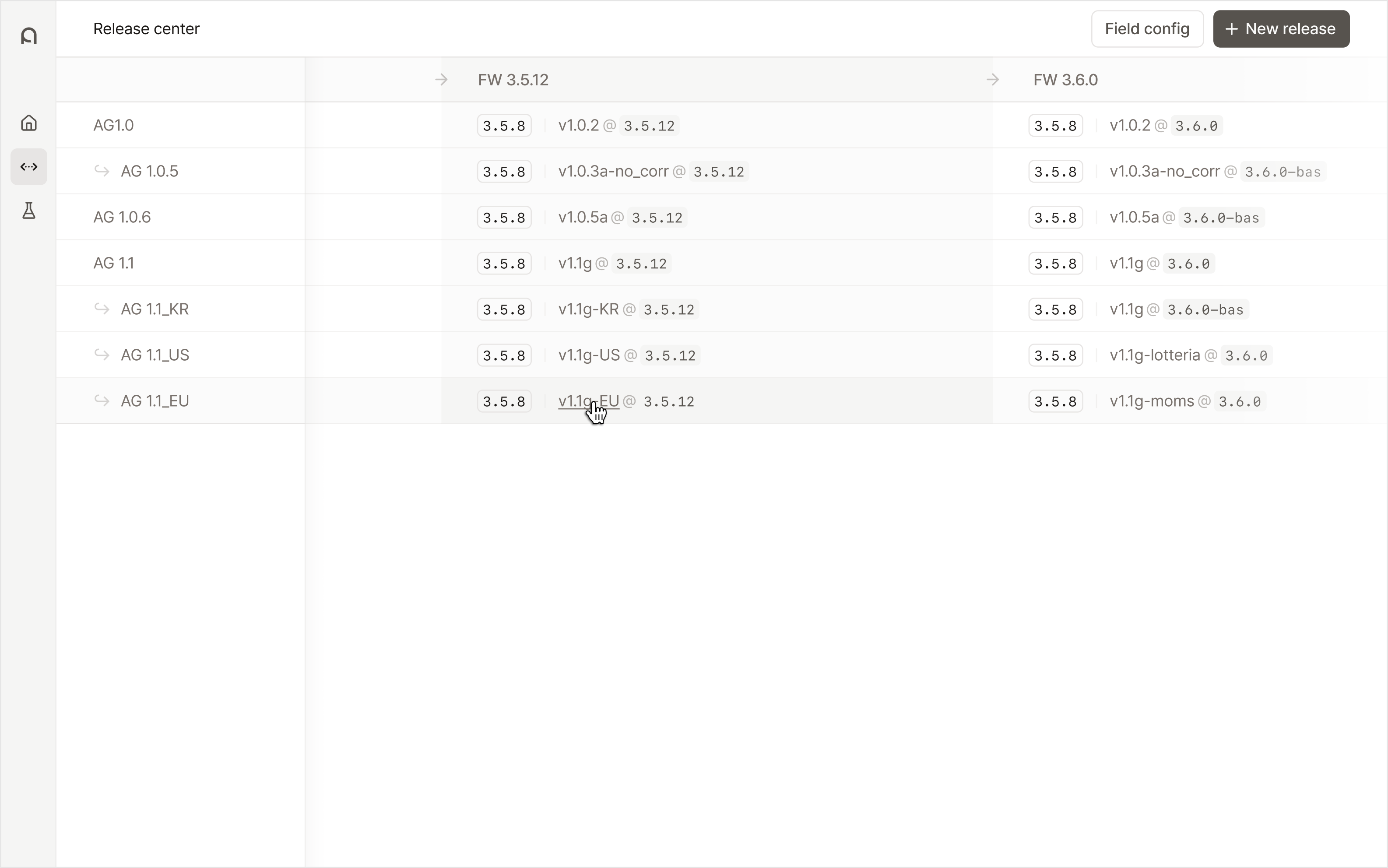

I shifted to managing updates by group instead of tracking each individual robot. At the hardware version level, everyone now had a single source of truth — replacing the scattered, product-by-product approach.

A key design challenge was creating a clear software update overview that helped all stakeholders quickly align. Since the naming system was hard to read at a glance, I focused on table layout and typography to make information scannable and easy to interpret2.

The design emphasized transparency and predictability, so that updates could scale smoothly across teams.

The system made update planning reliable — cutting update errors from 5% to 0%.

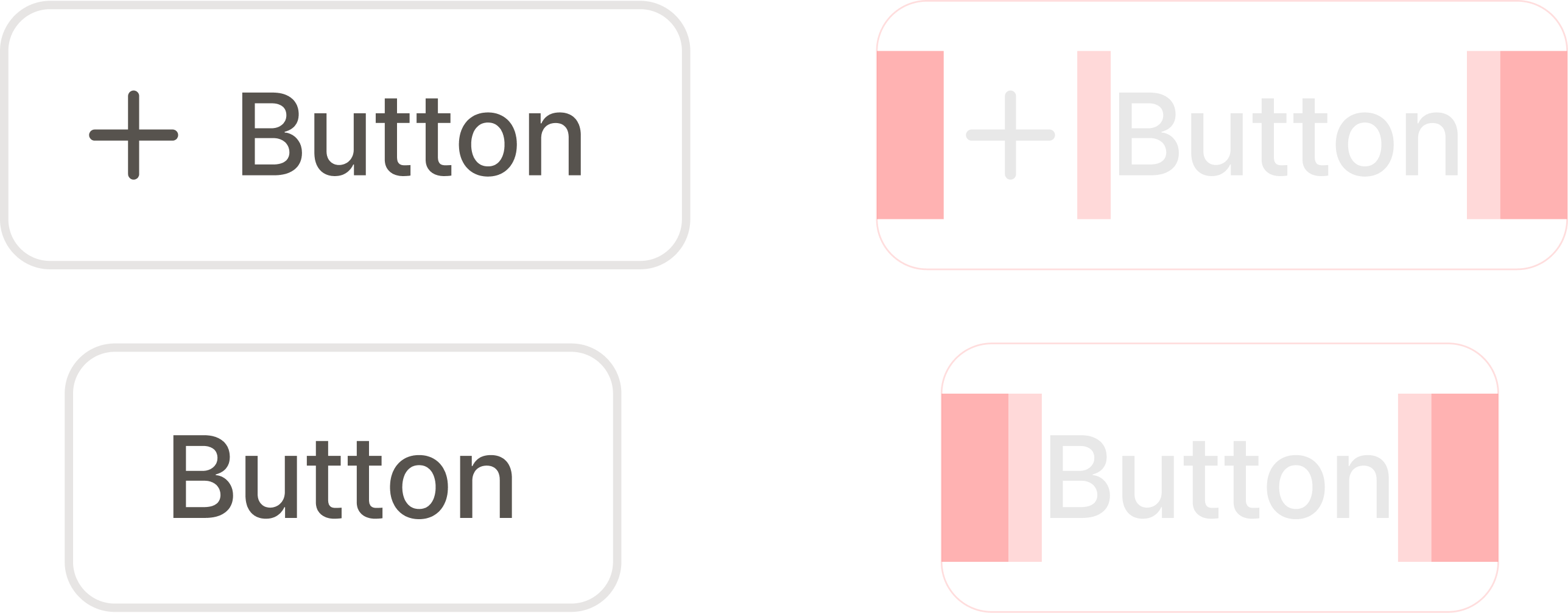

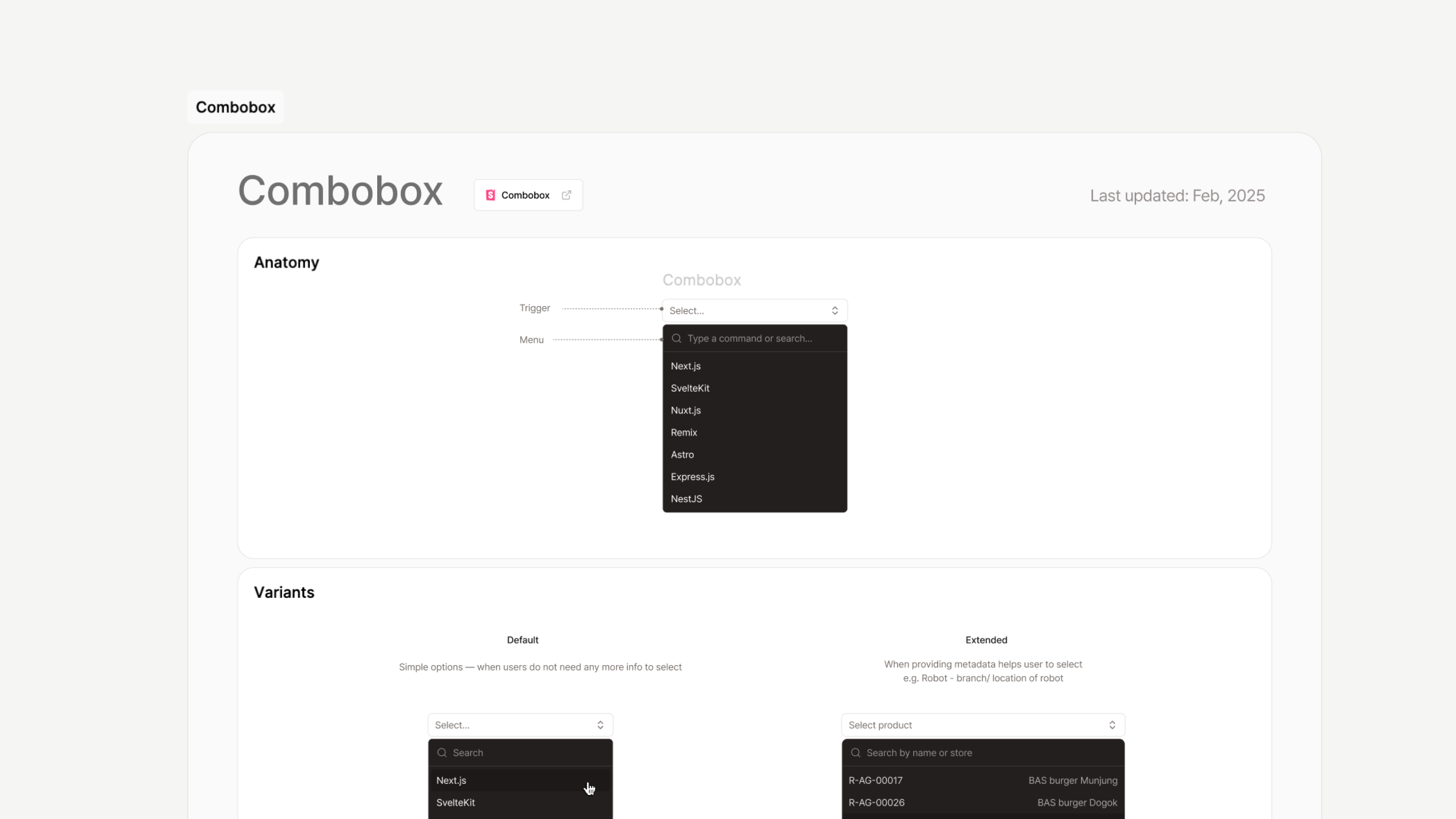

Building a foundation for fast, consistent design (2025)

Beyond shipping features, I worked closely with engineers to create an minimum viable design system for the internal tool.

As a team of two (me and SWE), we built on top of shadcn and tailored it to our product needs — helping us move faster. In about a month, we documented foundational tokens and built 14 production-ready core React components.

The design system was designed primarily for robot engineers, our core users, with high information density in mind. Typography, spacing, and color choices were refined for readability and consistency across tools.

The system gave the team a reliable foundation, speeding up interface development and ensuring consistency across products.

Closing thoughts

This work was highly collaborative, bringing together engineering, product, manufacturing, and customer success.

It pushed me to dive into robot development and manufacturing processes, and gave me the chance to rethink how we work across teams.